retort pouch

OUR PRODUCTS

Custom retort pocuh

Tired of retort pouches disasters ruining your food business?

We have the solution!

For food exporters like you, every defective retort pouch isn’t just waste; it’s a threat to your brand reputation, customer trust, and ultimately, profitability.Contact us, China Top 3 Retort pouches Manufacturer, maybe we can give you some suggestions.

Leave all your worries and difficulties to us

You may be worried about making mistakes because you’re not familiar with retort pouches. Don’t worry. We can provide retort pouch solutions tailored to your product and requirements. You just need to wait for our solutions and test samples.

Henan Baolai Packaging is a professional retort pouch manufacturer and solutions provider.

So what can we do for you?

1. We select materials based on the product and intended use to eliminate wrinkles in the pouches.

2. We use EU-standard printing inks to eliminate odor and discoloration.

3. Our unique lamination process and rigorous edge sealing eliminate product leakage.

4. We offer custom sizes.

5. With a daily production capacity of 500,000 pieces, you no longer have to worry about delivery times.

Contact For Custom Packaging

Leave all your worries and difficulties to us .

Let our team guide you through your customisation options and deliver the perfect pouch for your products.

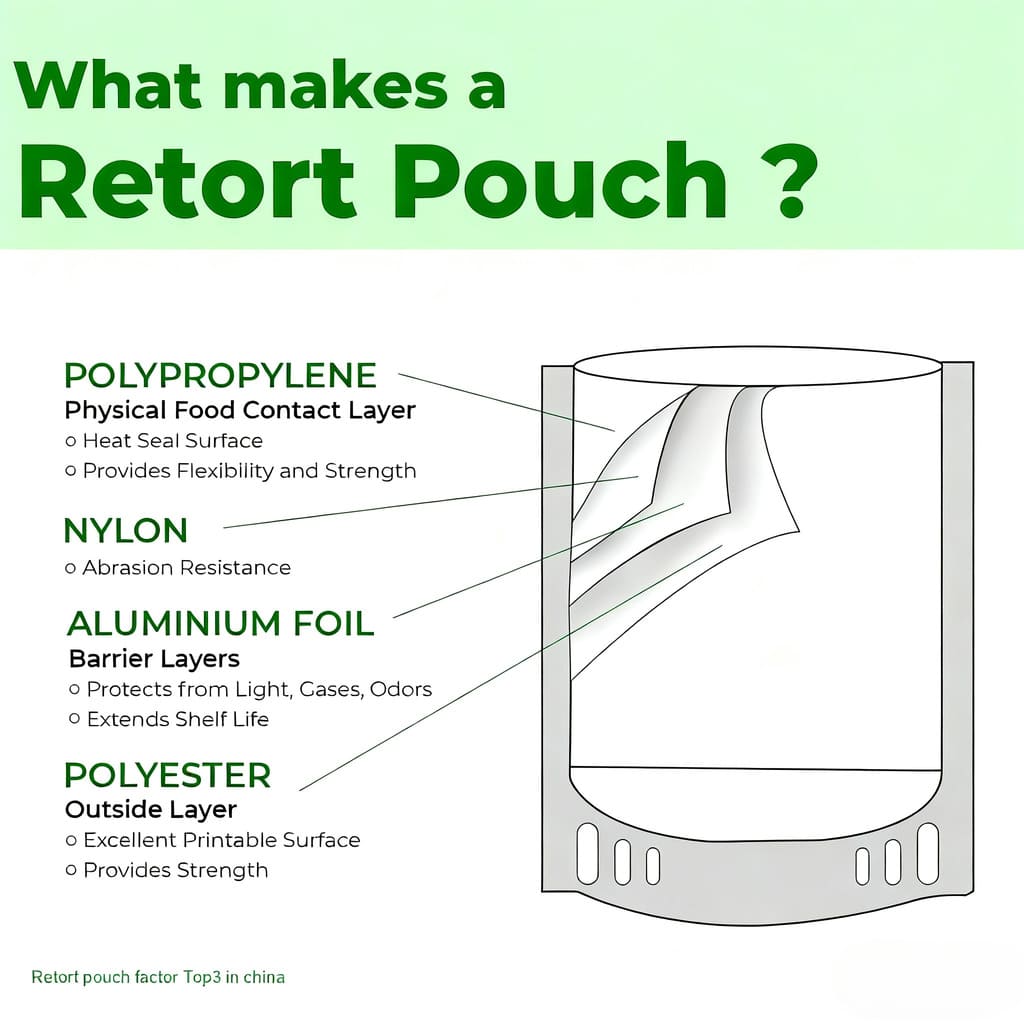

| Material | Function | Common composite roles |

| PET | Outer protection + printed display | Outer layer |

| AL | High barrier (oxygen / water / light) | Middle barrier layer |

| PA | Puncture resistant + oil resistant + low temperature resistant | Middle reinforcement layer |

| RCPP | High temperature heat seal layer | Inner layer (high temperature retort 100–135°C ) |

Advantages of retort pouches

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam

1. Easier to sterilize

Due to the flexibility of the material, they require lower temperatures during sterilization than other packaging bag.

5.Custom size&type

We offer fully custom retort bags, with no restrictions on size or shape – we can meet your exact requirements.

2. Efficient packaging

Packaging is faster. You can use heat sealing machines or integrated filling machines for heat sealing, reducing labor costs

6.Better printing quality

360° printing, ten-color printing, exquisite printing effects, attract consumers on the shelf and show your brand vision

3. Convenient storage

The flexible materials used in retort pouches mean they take up less space in storage, and there is less wasted space in warehouses.

7. Recyclable

Retort pouches boast globally viable recyclability: their materials align with recycling systems worldwide, while the all-in-one unit design makes proper disposal straightforward for consumers.

4. Convenient transportation

Transporting retort pouches at all stages of its lifecycle is cheaper due to how lightweight the packaging materials are.

8. Sustainable development

There are many global initiatives focused on improving the sustainability of all pouch packaging, meaning future development will improve retort pouches even further.

Contact For Custom Packaging

Leave all your worries and difficulties to us .

Let our team guide you through your customisation options and deliver the perfect pouch for your products.

Our solution cases

soup bag

fruit puree packaging

wet cat food pouch

dog treat squeeze pouch

ready to eat packaging

goat milk bag

ready meal packaging

moi moi cooking pouch

rice pouch

milk bag

Why choose Henan Baolai Packaging ?

Every big business starts from a small business. We are not only your partner, but also a member of your team.

01

Long-term partnership

The value of packaging goes beyond a single delivery; Henan Baolai Packaging adheres to the philosophy of long-termism and is committed to becoming your most solid partner in the development of your brand.

02

Sustainable Development

When packaging is no longer just the outer shell of a product, but a concrete expression of the concept of sustainability, Henan Baolai Packaging is redefining the value of packaging with green innovation.

03

Fully customized

Packaging is no longer a template, but a precise reproduction of the brand’s soul – Henan Baolai Packaging uses the power of “complete customization” to make each package an exclusive symbol that cannot be replicated.

04

20+ years experience

Choosing Henan Baolai Packaging means choosing a product that has been polished for 20 years – we understand packaging, and we know how to make packaging add points to your brand. Time is the best witness.

What products are retort pouch for?

tomato paste

baby food paste

tuna fish

snack

fried meat

soup

ready meal

Baby Porridge

egg

wet cat food

what is retort pouches ?

FAQ

What are your retort bags made of? Are they safe?

Our retort pouches are made of food-grade composite materials. The main structure is “PET (outer layer, heat-resistant and scratch-resistant) + AL (aluminum foil layer, light-proof, oxygen-blocking, and extending shelf life) + CPP (inner layer, retort-resistant, non-toxic and odorless).” Some products that don’t require light protection (such as transparent ones) use a “PET + PE” structure.

All materials are certified by international standards such as the FDA (U.S. Food and Drug Administration), EU No. 10/2011 (EU Food Contact Materials Directive), and SGS. They are free of harmful substances such as bisphenol A (BPA) and plasticizers, are suitable for direct food contact, and will not release toxic substances after high-temperature retorting. They meet the food packaging safety standards of major global markets.

What temperature can retort bags withstand?

Temperature range: The conventional model can withstand high temperatures of 135°C (suitable for high-pressure cooking, such as meat and canned food), and the low-temperature model can withstand -40°C (suitable for frozen foods, such as quick-frozen soups and pre-prepared dishes). The specific temperature resistance parameters will be marked on the product details page. You can choose according to your product processing needs before placing an order.

Are retort bags suitable for liquid/greasy products? Will they leak?

Yes. Our retort pouches feature an oil- and solvent-resistant inner layer of CPP/PE. The aluminum foil layer (or EVOH high-barrier layer) effectively blocks liquid penetration. For liquids (such as soups and sauces) and high-fat products (such as fried foods and canned meats), we also reinforce them with heat-sealed edges (width ≥ 8mm) and leak-proof bottom corners. Under normal use (undamaged and retorted at the specified temperature), they will prevent leakage.

If your product is highly acidic (such as kimchi and pickled foods) or high in salt (such as pickles), you can choose a corrosion-resistant material. Contact us service for details.

High-quality custom printed pouches in a range of styles

We specialize in custom packaging bags, each designed specifically for your product, making the packaging a truly unique and compelling addition. Our professional team will assist you throughout the entire customization process, from communication to proofing. Can’t find the perfect design? Tell us about your product’s characteristics and requirements, and we’ll create a customized solution to perfectly match your packaging to your product.

Spout pouch

Retort pouch

pouch with tap

3 side seal bag

Quad seal pouch

Custom shape

Contact For Custom Packaging

Spoilt for choice?

Let our team guide you through your customisation options and deliver the perfect pouch for your products.