How to choose retort pouch manufacturers

How to Choose a Reliable Retort Pouch Manufacturer ?

In recent years, flexible packaging has gained strong popularity in the global food market.In the pet food industry especially, driven by intense competition and the growing focus on circular economy, retort pouches have gradually become the mainstream packaging solution for modern wet pet food brands.For manufacturers, the key challenge is how to ensure food safety and nutritional stability while achieving lower total packaging costs and stronger market competitiveness.

Retort Pouches Require Much Higher Standard

Choosing a retort pouch supplier is fundamentally different from selecting packaging for snacks or so-called “soft cans”.Retort pouches must withstand sterilization temperatures of 121°C, and in some cases up to 135°C.If a supplier lacks the required technical expertise, it may lead to delamination, pouch swelling, seal failure, or even serious food safety incidents.

![]()

1. Material Structure: The Foundation of Safety and Appearance

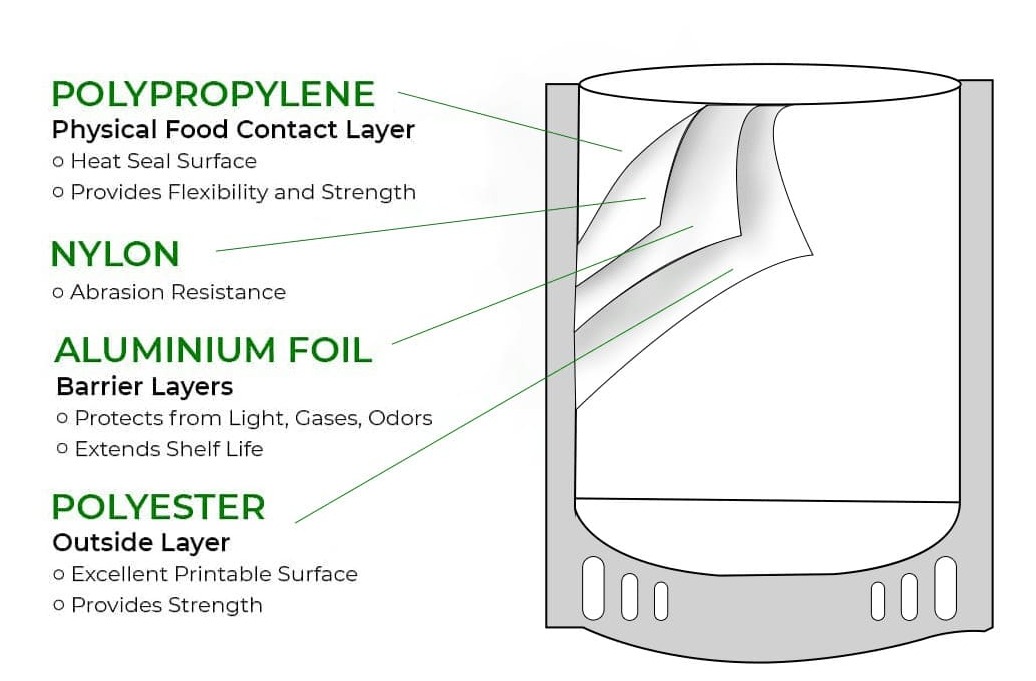

Material selection directly determines both the safety performance and the visual appearance of a retort pouch.At Henan Baolai Packaging, most of our wet pet food retort pouches are produced with three-layer or four-layer laminated structures.Currently, several large pet food contract manufacturers we cooperate with in Poland, Russia, and Spain use the following structure as a standard solution:PET / AL / PA / RCPP:This structure has been proven to reliably support high-temperature retort processing up to 135°C.

Printing Layer (PET):Provides excellent surface smoothness and mechanical strength. Suitable for high-definition gravure or flexographic printing, ensuring vivid colors and strong shelf appeal.

Core Barrier Layer (AL – Aluminum Foil):Offers outstanding oxygen, moisture, and light barrier properties, effectively preventing oxidation and moisture ingress, significantly extending shelf life.

Reinforcement Layer (PA – Nylon):Enhances puncture resistance and impact strength, improving overall pouch durability during filling, sterilization, transportation, and storage.

Inner Sealant Layer (RCPP):Provides stable heat sealing performance and excellent resistance to high-temperature retort processing, meeting food-grade safety requirements.

Ink Quality Also MattersInk quality plays a critical role in both print performance and food safety.

At Henan Baolai Packaging, we strictly use EU-compliant food-grade inks, with procurement standards and costs higher than the industry average.This is not a short-term cost decision, but a long-term commitment to consumer safety and brand reputation.

2. Manufacturing Process and Technical Capability

Even with the correct material structure, insufficient lamination control, curing conditions, or seal design can still result in delamination, swelling, or seal failure during retort sterilization.To reliably withstand 121°C–135°C processing, a retort pouch manufacturer must possess the following core capabilities:High-stability lamination process,Fully controlled curing cycles,Heat seal structures designed specifically for retort condition,Actual 121°C / 135°C retort simulation testing.At Henan Baolai Packaging, the use of high-quality adhesives and extended curing time is one of the reasons why our retort pouch production cycle is longer than ordinary packaging.All wet pet food retort pouches are validated through real high-temperature sterilization before mass production.

3. Quality Control and Testing Standards

A pouch that “looks fine” does not guarantee safety under real retort and distribution conditions.At Henan Baolai Packaging, every wet pet food retort pouch must pass the following tests:Peel strength test, Seal strength test,Burst test,High-temperature retort validation test.Only suppliers with a complete testing system and continuous quality control can truly ensure retort pouch safety.

4. Project Experience and Risk AwarenessRetort pouches are not standardized products.

Different formulations, oil content, moisture levels, filling methods, and sterilization conditions require different structural considerations.Experienced suppliers prioritize risk over cost and communicate clear technical boundaries, helping customers reduce trial-and-error and ensure stable mass production.

Why Choose Henan Baolai Packaging

Choose retort pouch supplier is ultimately a decision about food safety, brand reputation, and long-term production stability.

Henan Baolai Packaging specializes in high-barrier flexible packaging solutions, with extensive experience in wet pet food retort pouches.

We provide mature structures such as PET/AL/PA/RCPP supporting 121°C–135°C sterilization, and in 2025, we successfully achieved stable application of 121°C retort zipper pouches.

We believe a reliable retort pouch supplier is not just a manufacturer, but a long-term partner who understands products, processes, and risks.